07

2025

-

05

Zhengzhou Ward Superhard Materials Co., Ltd. Showcases at the 19th China International Machine Tool Show (CIMT2025) - Promoting Intelligent Manufacturing and Precision Machining with Innovative Products

May 07,2025

Business Negotiation: A dedicated one-on-one area is set up on-site to provide procurement agents with Free sample trial and Customized cooperation plan to accelerate collaborative innovation across the industrial chain.

II. Industry Trends:

Currently, the total output value of China's superhard materials industry has exceeded 15 billion yuan. Driven by both policy support and market demand, it is accelerating towards two major trends: precision application and functional transformation, introducing high-efficiency processing and excellent polishing quality to promote a new pattern of precision processing.

III. Booth Highlights:

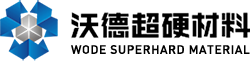

- Product features:

Gray-green color, polycrystalline structure, irregular shape and uneven surface. The rough surface has good grip with the binder. The good self-sharpening ability of this diamond greatly improves the grinding efficiency while ensuring the service life of the tool.

- Application range:

1. Ceramic floor tiles, high-end stone materials

2. Silicon nitride, porcelain, alumina, silicon carbide, glass, etc.

3. Polishing and grinding of PCD/PCBN

Available particle size: 60/80-400/500

2. CBN Cubic Boron Nitride Series

Cubic boron nitride (CBN) is a superhard material with hardness second only to diamond, and its thermal stability is superior to that of diamond. It is suitable for grinding quenched steel and super-heat-resistant alloy materials, with high grinding efficiency, long service life, and improved part quality and stable consistency. It not only has many excellent properties of diamond but also has higher thermal stability and does not react with iron elements, showing its chemical inertness to metals and alloys. As an engineering material, it has been widely used in the processing industry of ferrous metals and their alloys. At the same time, with its excellent thermal, electrical, optical, and acoustic properties, it has been well applied in many high-tech fields, becoming a functional material with development prospects.

Ward Production: Amber diamond WBN90, dark brown WBN88, WBN80T, WBN50, WBN30, WBN20 (high brittleness, polycrystalline)

Widely used in: resin, ceramics, electroplating, metal-bonded abrasives and tools.

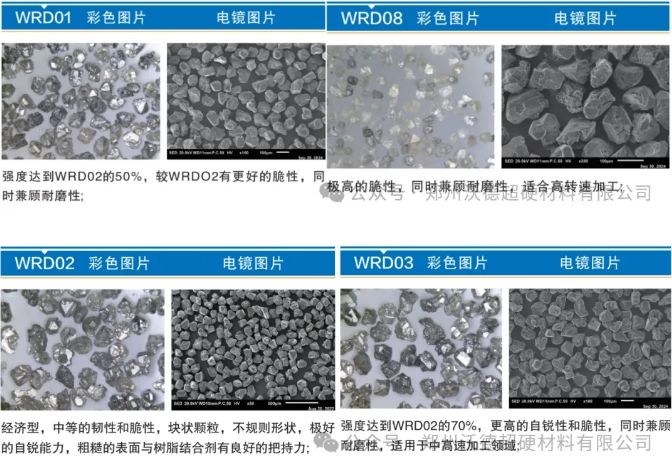

3. Polycrystalline-like series

- Product features: Made of microcrystalline diamond, surface functionalized, high polishing efficiency, high removal rate, and scratch-free.

- Application fields: Ceramic cover plates, crystal materials, glass thinning, etc.

- Industry case: Removal rate of Chu crystal optical material polishing increased by 50%

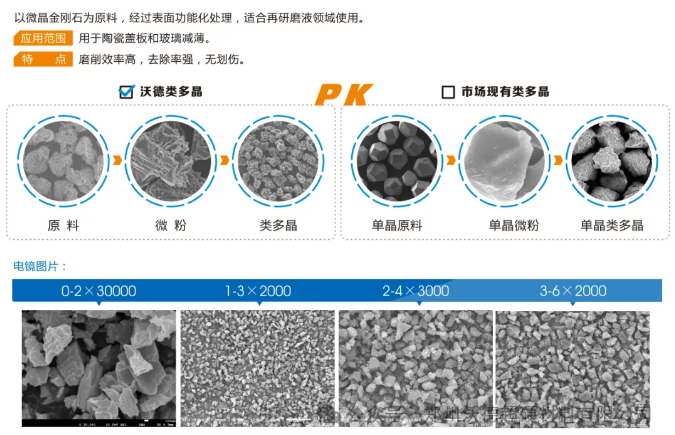

4. Nano-diamond micropowder

- Product features: It has strong covalent bonds and strong lipophilic and hydrophobic properties, good compressive performance and repair function, high thermal conductivity, extremely narrow and uniform distribution of nanoparticles, and ultra-smooth surfaces can be obtained by ultra-precision polishing or grinding.

- Industry case: Used in mechanical bearings, tool surface coatings (nano-diamond-titanium composite coatings) to improve high-temperature resistance and wear resistance.

IV. About Zhengzhou Ward Superhard Materials Co., Ltd.

As a national-level specialized and new technology enterprise, Ward Company, under the leadership of General Manager Zhou Shijie, has been deeply engaged in the superhard materials field for more than ten years and has More than 38 patents (including 4 invention patents). Products are exported to more than 30 countries and regions including Europe, America, Japan, and South Korea, serving Fortune 500 manufacturing companies worldwide. The company has passed international certifications such as ISO9001 and ISO14001, and with “Technology + Service” dual engine model, continuously creating value for customers.

CIMT2025 is not only a stage to showcase hard-core strength but also a bridge to connect global intelligent manufacturing. Zhengzhou Ward Superhard Materials Co., Ltd. sincerely invites industry colleagues to gather at Ward for discussions, explore the infinite possibilities of superhard materials, and work together to promote China's high-end manufacturing to new heights.

More information

Contact Information

Tel: 0086-371-68198011

Whatsapp: +86 18736072307

E-mail: yhz@wodediamond.com

Address: No. 9, Danxia Road, Shangjie District, Zhengzhou City, Henan Province

Online Message

Leave your contact information and get a free product quote

Copyright © 2024 ZHENGZHOU WODE SUPERHARD MATERIAL CO., LTD.