PCBN-polycrystalline cubic boron nitride insert for cutting

Classification:

Wode cutting tool with PCBN insert as a synthetic CBN powder and metal/ceramic bond for high temperature and high pressure sintering of high hardness tool material, with high hardness (I. e. high wear resistance), high thermal stability and the iron group metal and its alloy chemical inertness and so on. Widely applicable to the processing of HRC45-65 ferrous metal materials. Such as: high-speed steel, bearing steel, cast iron, etc., usually used to process brake discs, engine pistons, engine cylinders, brake drums, flywheels, valve seats, gears, transmissions and abrasive tools. The surface finish of the processed workpiece is high, which can be realized by turning instead of grinding, greatly improving labor efficiency and effectively reducing production costs.

PCBN is divided into low content and high content according to CBN content.

Wode CBN blades are composed of BNC and BNS two series of products.

1, BNC series products-by polycrystalline cubic boron nitride layer and hard alloy layer composite, with good weldability, good wear resistance, high fracture strength, good chemical stability, high dimensional accuracy of the workpiece processing, processing good consistency and other characteristics.

2. BNS series products-pure PCBN polycrystalline, no hard alloy substrate. It has the characteristics of good wear resistance, good high temperature resistance, high fracture resistance, multiple cutting edges on both sides and high cost performance.

Production equipment

Production equipment

Production equipment

Production equipment

Production equipment

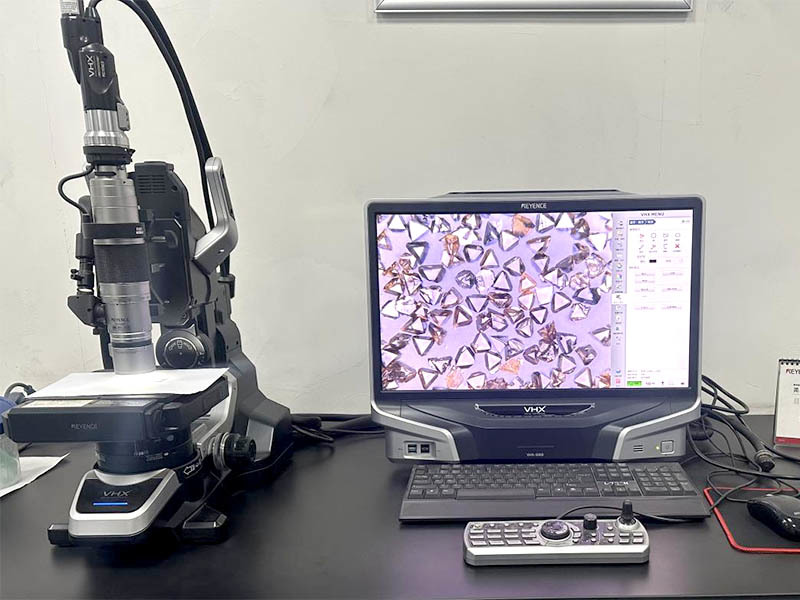

Testing equipment

Color difference meter

Malvern Mastersize2000 Laser Particle Size Analyzer

Diamond magnetic susceptibility analyzer

Keenz

Appearance of the factory

Gate

Exhibition hall

Detection device

Appearance of the factory

Key words:

Get a free product quote

Leave your contact information and get a free product quote

Contact Information

Tel: 0086-371-68198011

Whatsapp: +86 18736072307

E-mail: yhz@wodediamond.com

Address: No. 9, Danxia Road, Shangjie District, Zhengzhou City, Henan Province

Online Message

Leave your contact information and get a free product quote

Copyright © 2024 ZHENGZHOU WODE SUPERHARD MATERIAL CO., LTD.